Keep Your Mill Rolling: Top 5 Causes of Cold Rolling Mill Bearing Failure

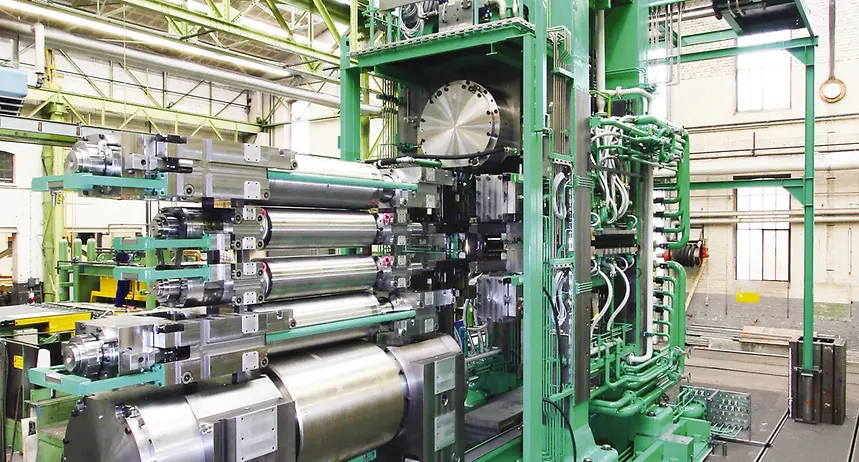

Cold rolling mill bearings are the unsung heroes of your production line. Engineered to withstand crushing loads, high speeds, and the harsh environment of the mill (think heat, water, and abrasive scale), they are significantly more robust than standard bearings – often rated for 2 to 5 times the load. Yet, they remain a critical point of vulnerability. Bearing failure doesn't just mean downtime; it can directly impact the quality of your cold rolled products.

Understanding why these vital cold rolling mill bearings fail is the first step towards maximizing their lifespan and your mill's uptime. Based on extensive operational analysis, here are the top 5 culprits:

1. Raceway Fatigue & Contamination: The Silent Grind

The Problem: Over time, the inner and outer raceways of bearings experience wear. Poor lubrication dramatically accelerates this. Microscopic material flakes off the surfaces, accumulates between rolling elements and raceways, concentrates stress, and initiates cracks. This leads to spalling (pitting), surface degradation (creating a "peppered" appearance), and ultimately, catastrophic failure.

The Root Cause - Lubrication Breakdown:

Seal Failure: Worn labyrinth seals (formed by the bearing housing and water baffle) are enemy #1. Causes include misalignment during assembly, housing damage impacting the seal gap, axial movement of the inner ring loosening the baffle, or degraded rubber seals/springs losing elasticity.

Emulsion Invasion: Failed seals allow rolling emulsion to leak into the bearing housing. This dilutes the grease/oil, stripping away its lubricating properties – a common issue for lower roll bearings.

2. Overheating, Discoloration & Softening: The Vicious Cycle

The Problem: Severe temperature spikes cause bearing rings to discolor (often blue or brown) and lose hardness.

The Root Cause: High heat causes the interference fit between the inner ring and the roll neck, or the outer ring and the housing, to loosen. This allows relative slippage ("creep"), generating even more friction and heat. Axial loosening (e.g., loose end bolts or bolt failure under excessive axial load) is a major trigger for inner ring slippage ("running inner ring").

3. Catastrophic Failure: Fracture & Seizure (The Worst-Case Scenario)

The Problem: Extreme overheating, loud noises, smoking, and complete bearing lock-up signal imminent disaster.

The Root Causes:

Poor Fit/Geometry: Cold mill rolls and their housings must perfectly support the thin, hard, but relatively brittle bearing rings. Worn, damaged, or out-of-spec rolls/housings (developing grooves, ovality, or severe deformation) force the rings to bear loads alone, leading to fracture.

Shock Loads: Strip breaks, cobbles, or severe overloads (especially with inadequate protection systems) deliver massive impacts. This can cause rings to fracture, rolling elements to shatter, cages to break, and induce severe "running ring" issues or total seizure.

Assembly Errors: Installing bearings onto damaged rolls/housings, or ignoring known geometry issues, is a recipe for rapid, catastrophic failure under mill loads.

4. Excessive Radial Loads: Bending the Rules

The Problem: While designed for high rolling forces, sustained peak pressures or uneven loading drastically shortens bearing life. Rolling element fracture, cage damage, and accelerated raceway wear are common results.

The Root Causes:

Work Roll Bending: Essential for controlling strip shape, applying bending force through the housing creates highly uneven radial loads on the bearing. Load concentrates on just a few rolling elements, significantly reducing the bearing's effective load capacity and causing localized raceway wear.

Wedge-Shaped Material: Leads to severe single-side loading, overstressing one section of the bearing.

5. The Hidden Threat: Excessive Axial Loads

The Problem: Often underestimated, axial forces can be devastating. They cause roll shifting ("float"), break axial retention bolts, and can lead to complete bearing meltdown.

The Root Cause: While theoretically 1-2% of rolling force, axial loads can easily reach 5% or more in practice. The primary cause is roll crossing (misalignment of roll axes), especially on driven rolls. Other factors include asymmetrical rolling and unstable drive systems.

Protect Your Rolls, Protect Your Profit

Failure of cold rolling mill bearings is complex, but rarely random. By focusing on these key areas – robust sealing and lubrication management, precise roll and housing geometry maintenance, vigilant monitoring for overheating and vibration, controlling process stability to minimize shocks and axial loads, and meticulous assembly practices – you can significantly extend bearing life, reduce costly unplanned downtime, and ensure the consistent production of high-quality cold rolled strip.

Proactive maintenance and understanding these failure mechanisms are your best defense against bearing failure. Invest in precision, invest in monitoring, and keep your mill rolling efficiently.