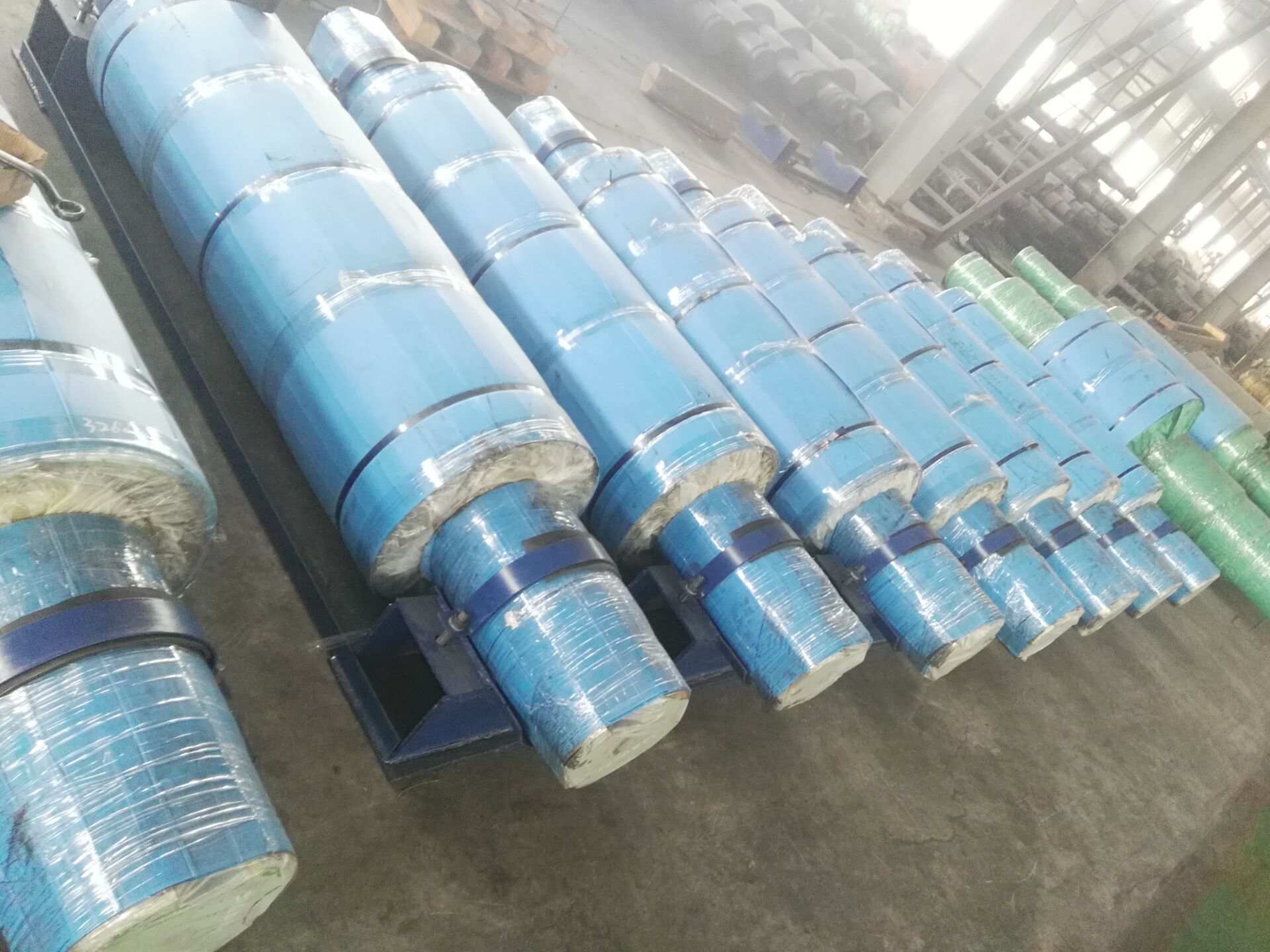

Alloy Cr Ni Mo V Cast Steel Roll

Alloy Cast Steel Roll materials are eutectoid steel and hypereutectoid steel. Adding alloy content such as Cr, Ni, Mo, and V up to more than 0.8%, carbon content 0.4~1.3%. The matrix structure, after heat treatment of normalizing and tempering, becomes sorbite and tempered sorbite. This type of steel mill roll possesses high strength, good toughness, good resistance to hot cracking, and strong impact resistance.

The cast steel roll employs monoblock casting process (single pour): Melting-Casting-Heat Treatment-Machining-Flaw Detection-Finished Products.

It can be work rolls for blooming and slab mills, section roughing mill rolls, as well as backup rolls for hot-strip steel rolling mills.

TINVO's alloy cast steel mill rolls conform to international standards, including ISO, GB, ASTM, DIN, and JIS.

Chemical Composition

Cast Steel | C | Si | Mn | P | S | Ni | Cr | Mo |

ZuS60SiCrNiMo | 0.55~0.65 | 0.20~0.45 | 0.90~1.20 | ≤0.035 | ≤0.030 | 0.80~1.20 | 0.30~0.45 | |

ZuS65SiCrNiMo | 0.60~0.70 | 0.20~0.60 | 0.50~0.80 | ≤0.035 | ≤0.030 | 0.30~0.80 | 0.80~1.20 | 0.30~0.45 |

Zu70Mn | 0.65~0.75 | 0.20~0.45 | 0.80~1.40 | ≤0.035 | ≤0.030 | |||

Zu70Mn2 | 0.65~0.75 | 0.20~0.45 | 1.40~1.80 | ≤0.035 | ≤0.030 | |||

Zu75CrMo | 0.70~0.80 | 0.20~0.45 | 0.60~0.90 | ≤0.035 | ≤0.030 | 0.75~1.00 | 0.30~0.45 | |

Zu75CrNiMnMo | 0.70~0.80 | 0.20~0.60 | 0.60~1.10 | ≤0.035 | ≤0.030 | 0.30~1.00 | 0.90~1.20 | 0.30~0.45 |

Zu75Cr3NiMo | 0.70~0.80 | 0.20~0.60 | 0.60~1.10 | ≤0.035 | ≤0.030 | 0.50~1.50 | 2.50~3.00 | 0.30~0.45 |

Zu80Cr | 0.70~0.85 | 0.20~0.60 | 0.60~1.10 | ≤0.035 | ≤0.030 | 0.50~1.50 | 2.50~3.00 | 0.30~0.45 |

Physical Properties

Cast Steel | Roll-body hardness HSD | Tensile strength Mpa | Tension% | ToughnessJ/cm |

ZuS60SiCrNiMo | 32~42 | ≥740 | ≥5 | ≥8 |