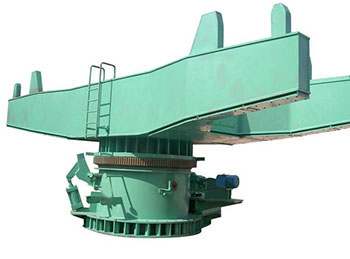

Φ80-150 Round Billet Continuous Casting Machine

Φ80-150 Round Billet Continuous Casting Machine

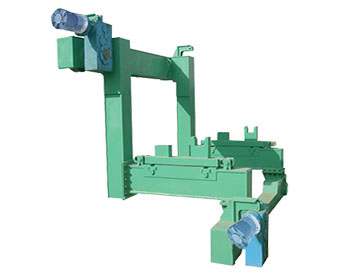

The continuous casting (CC) round billet refers to a machine that mainly produces tube blanks for seamless steel pipes and it adopts continuous cast steel iron-making technology. It is mainly composed of the ladle, tundish, mold (primary cooling), mold oscillating unit, secondary cooling and casting billet guide device, withdrawal and straightening unit, cutting unit, billet discharge unit (conveying roller), etc. The completely solidified straight billet will be cut into the required size by cutting equipment and transported to the subsequent process by conveying roller. The equipment used for continuous casting steel production is actually the complete set of mechanical equipment in the continuous casting production line.

The production process of continuously casting high-temperature molten steel into a slab with a certain cross-sectional shape and a certain size is called continuous casting steel. The equipment required to complete this process is called a continuous casting machine (CCM). The electromechanical-hydraulic integration of the steel casting equipment such as the body equipment, the cutting area equipment, the dummy rod collection and conveying equipment constitutes the core equipment of continuous steel casting.