CNC Turning

CNC Turning

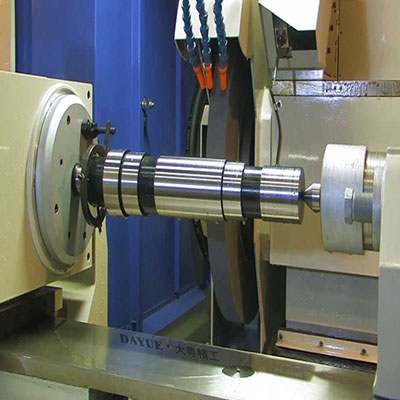

CNC turning is a typical subtractive manufacturing process, which uses cutting tools to remove parts of the material from the outside. When the workpiece is rotating (continuously rotating), the excess debris is shaved off until the ideal shape, diameter and size of the final product are reached. CNC turning is suitable for cutting metals, woods, plastics and other polymers. In addition, because this process uses computer-generated programs and codes, its products often have high dimensional accuracy.

Turning includes rotating and turning the workpiece. Usually, the material being processed is cylindrical or circular. However, when using a compatible adapter, turning can play a role on mterials of different shapes.

Types of CNC turning operations

Straight turning

Knurling

Splitting

Tapered turning

Thread processing

Slotting

Materials suitable for CNC turning processing

One of the significant advantages of CNC processing is its compatibility with a large number of materials. Similarly, most metal and plastic materials are ideal choices for CNC turning processing:

Aluminum

Nylon

Copper

Steel

Wood

Titanium alloy

PEEK

ABS

Glass

PVC

Brass

Wax, etc.

Because each material has different structural integrity, it may require unique specifications of different lathes or turning centers, such as feed rate and turning speed.

If you need CNC machining service, leave a message for more details.