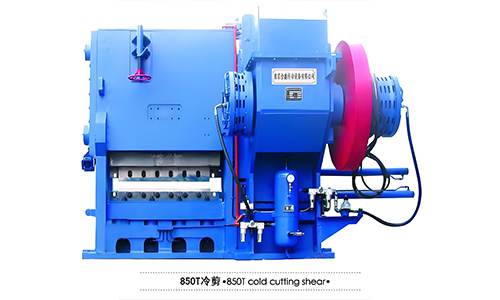

650T-1300T Cold Shear

Cold shear is a kind of equipment that shears metal materials at normal temperature. It is often used for operations such as fixed-length cutting of rolled metal profiles or plates.

Parameter

Maximum shearing force: 8330 KN to 13000 KN.

Shear blade width: 1250 - 2000 mm.

Opening degree: ≥ 135 to ≥ 200.

Shearing frequency: 15 to 18.

Cold shear plays an important role in the rolling mills. The machine has high strength capacity to cut the product into desired lengths. It adopts a ball screw, linear guide and servo motor to drive the back gauge with high positioning accuracy with integrated steel welded structure, eliminate stress by vibration, with good rigidity. The serials' connection of the oil cylinder is to prevent the cutting angle changing during the operation of the fly shearing machine. It has the automatic adjustment of blade clearance for accurate, rapid and convenient operation. The adjustable shear angle is to reduce sheet distortion. Motorized back gauge and position display make it convenient and precise.

Feature of Cold Shear:

The housing is a closed frame structure, which adopts mechanical transmission. After starting the machine tool, the motor drives the flywheel to rotate on the high-speed gear shaft. When cutting starts, the footswitch is first operated by pressing the material, and then the footswitch of the machine tool is operated to suction compressed air into the solenoid. The solenoid sends compressed air to the cylinder to push the piston, which causes the friction clutch to mesh with the flywheel, then drives the starting gear to rotate, and then transfers from the starting gear to the intermediate gear. A small gear is transmitted to the large gear on the crankshaft. The crankshaft is connected to the slider through a connecting rod, and the slider moves up and down. During a single movement, the slider moves up and down one round to complete a shear. A pneumatic friction clutch brake is used to make the machine operation stable, flexible and reliable.

The mechanical transmission gears are all arc gears, which have a much longer life than common involute gears.

Lubrication is a concentrated lubrication of thin oil. The thin oil station is driven by the pull rod on the crankshaft so that the lubricant is continuously sent to each guide surface and sliding point.