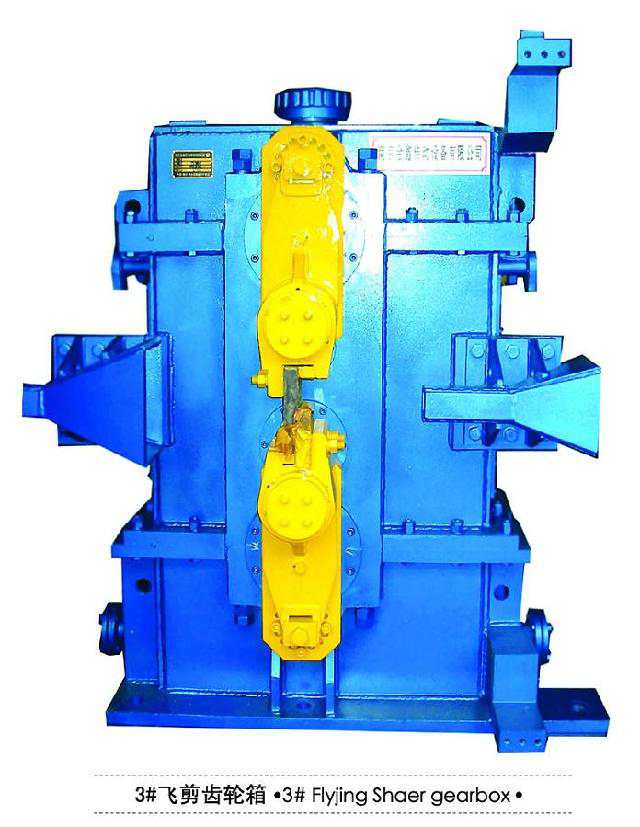

Crank and Rotary Combined Flying Shear

The 1#, 2#, and 3# flying shears belong to hot shears and are a type of flying shear machine. They are mainly used in the bar, wire rod and section steel production lines of steel mills to cut the heads and tails of rolled pieces, conduct emergency fragmentation and segment them into multiple lengths.

The flying shears designed and manufactured by TINVO can meet the requirements of modern rolling technology for large rolling sections and high rolling speeds. We can conduct customization according to the actual needs of customers to meet the individualized rolling technology requirements, such as flying shears for channel steel, angle steel, and other section steels.

Classification and Main Parameters

According to the different layout positions and shearing specifications of the flying shears in the steel mill, they are divided into 1# flying shear, 2# flying shear, and 3# flying shear.

· The 1# flying shear is located in front of the medium rolling unit, and normally in front of the 7H rolling mill gearbox.

· The 2# flying shear is located in front of the finish rolling unit, and normally in front of the 13H rolling mill gearbox.

· The 3# flying shear is located after the finish rolling unit, generally behind the 18th stand.

No | Fly shear | Structure | Nickname | Function | Rolled piece | Position | Work pattern | Shear section(mm) | Rolling temperature(℃) | Rolling Speed(m/s) |

1 | 1# fly shear | Crank | Crank flying shear | Cut head and tails | Long steel, small section steel | Behind rough rolling mill | Start/Stop | ≤Φ140 | ≥850℃ | 0.4~2.5 |

2 | 2# fly shear | Rotary | Rotary flying shear | emergency fragmentation | Long steel, | Behind intermediate rolling mill | Start/Stop | ≤Φ55 | ≥850℃ | 3~8 |

3 | 3# fly shear | Crank and Rotary | Crank and Rotary flying shear | segment into multiple lengths. | Long steel, small section steel | Behind finished rolling mill | Start/Stop | ≤Φ70 | ≥550℃ | 3~20 |

4 | 4# fly shear | Rotary | / | / | / | / | Start/Stop | ≤Φ24 | ≥800℃ | 8~22 |

5 | Gantry fly shear | Gantry | / | / | Large bar | Behind rough rolling mill | Start/Stop | ≤Φ200 | ≥850℃ | 0.5~1.8 |