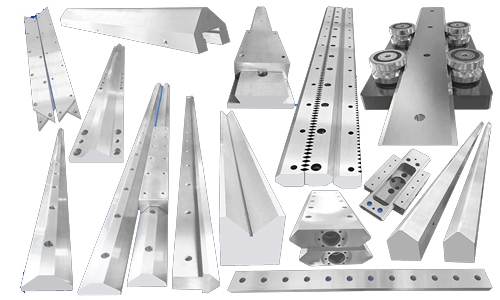

Machine Tool Guide Rail

The part that supports and guides the moving components to move along the trajectory is called the guide rail. The movement trajectory of the moving parts includes straight lines, circles or curves. The rolling circular guide rail can be classified into the rolling thrust bearing, and the curved guide rail is less applied in machinery.

The guide rail is a very important part in the machine. The machining accuracy of the machine tool has a direct connection with the guide rail accuracy. For the machine tools in small-batch production, the machining workload of the guide rail accounts for about 40% of the entire machining workload of the machine tool. Moreover, once the guide rail is damaged, it is difficult to repair. According to the kinematics principle, the so-called guide rail is a device that restricts the moving component to only one degree of freedom.

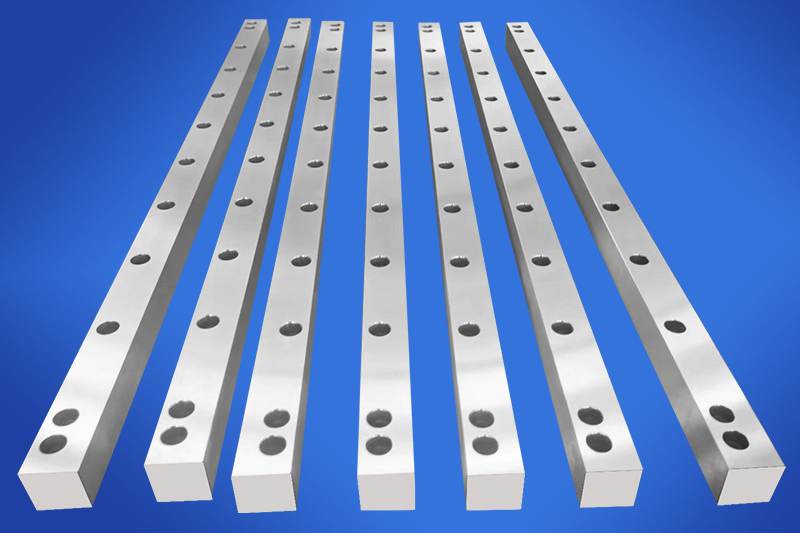

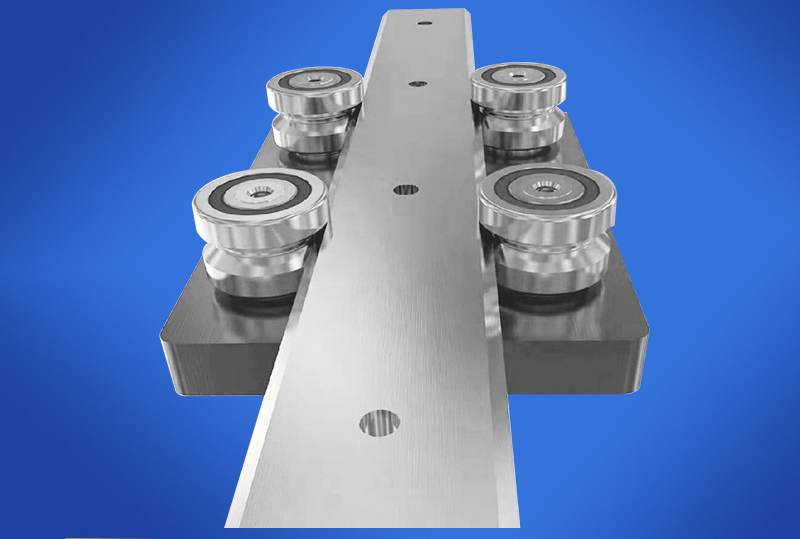

The guide rail surface set on the supporting component is the supporting guide surface, which is called the static guide rail and it is relatively long; the other guide rail surface is set on the moving component and is called the moving guide rail, which is relatively short. The moving component with the moving guide rail is often called the worktable or the sliding table. The commonly used guide rail surfaces include plane and arc surfaces. The arc guide rail surface forms a cylindrical guide rail; different planar guide rail surfaces are combined to form a rectangular guide rail. The friction between the guide rail surfaces is called a sliding guide rail if it is sliding friction, and it is called a rolling guide rail if rolling elements are placed between the guide rail surfaces to convert the friction into rolling friction.

The guide rails can be divided into closed type and open type. The closed type guide rail can bear the overturning moment while the open type guide rail cannot.

If you need guide rails manufacturing, leave a message for futher details.