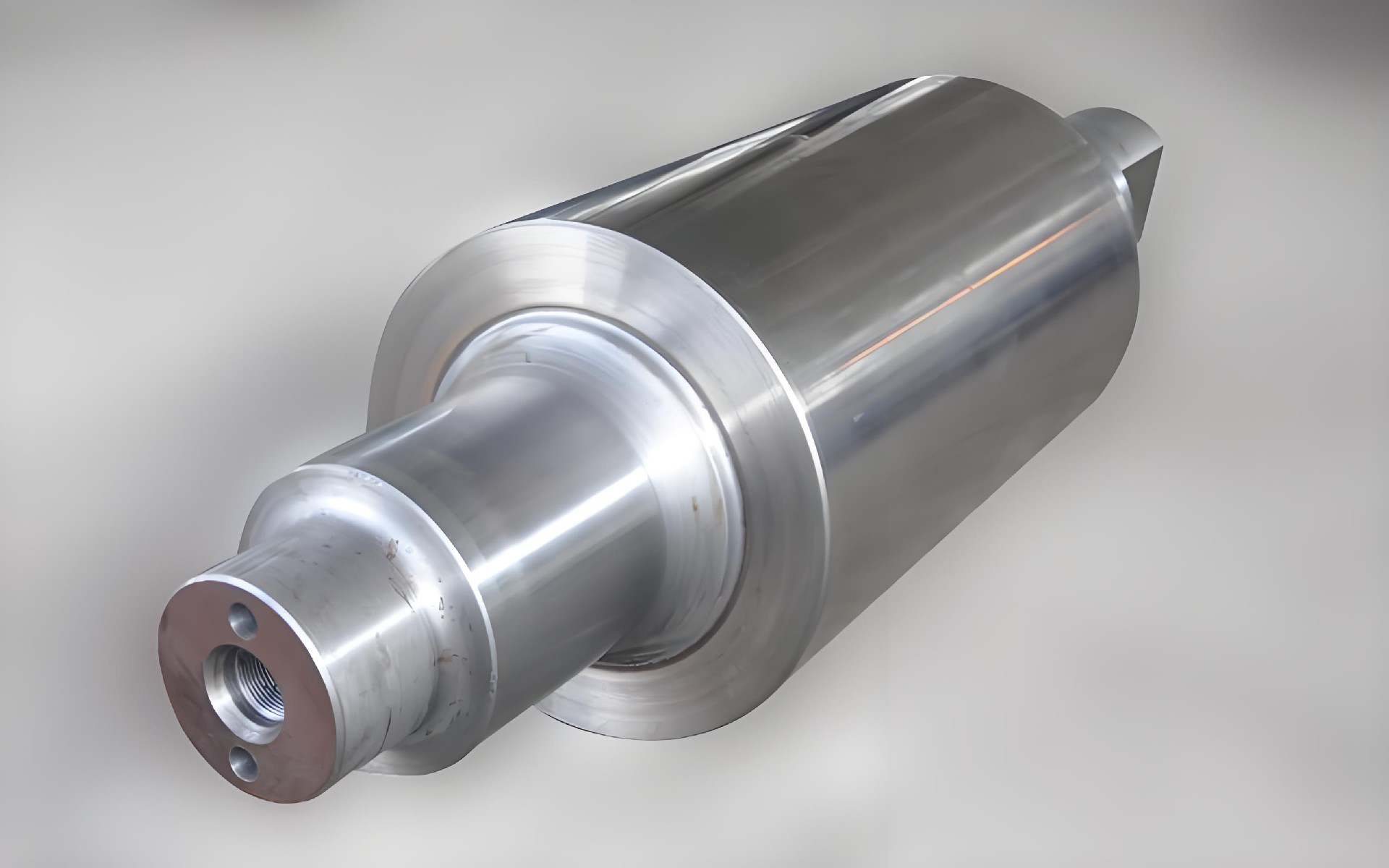

HSS Roll

High speed steel roll known as HSS roll are a kind of hot roll material with excellent performance. The application of high speed steel roll is an important component of the development of modern steel rolling production and another major technological change in the development of the steel industry. High speed steel rollers have higher hardness and wear resistance than traditional rollers. The centrifugal casting high-speed steel rollers have been widely used in the production of hot-rolled narrow strip steel, sheet steel, section steel, rebar, spring flat steel, high-speed wire and other fields. They are not only used for working rolls, but also for the back-up rolls.

Characteristics & Advantages:

· High-speed steel roll materials contain high alloy elements such as vanadium, tungsten, chromium, molybdenum, and niobium. The types of carbides in the roll structure are mainly MC and M2C. Comparing with ductile iron rolls with high-nickel-chromium rolls, the steel passing volume is high each time, which saves time of roll changing, improves mill operating efficiency and reduces production costs.

· High-speed steel rolls have good thermal stability. At the rolling temperature, the roll surface has higher hardness and good wear resistance.

· High-speed steel rolls have good hardenability, and the hardness from the surface of the roll body to the inside of the working layer rarely decreases, thereby ensuring that therolls have equally good wear resistance from the outside to the inside.

· During the use of high-speed steel rolls, under good cooling conditions, a thin and dense oxide film is formed on the surface of the roll body. This uniform, thin and dense oxide film can exist for a long time without falling off, making the high-speed steel rolls wear-resistant significantly improved.

· High-speed steel rolls have a large material expansion coefficient and good thermal conductivity. The HSS rolls continue to shrink due to the expansion of the high-speed steel materials themselves. During the rolling process, the change of the rolling groove is small, and the consistency of the hole size is maintained for a long time, especially when rolling the bar or rebar, which is more conducive to controlling the negative tolerance of the rolling material.

· The core of the centrifugally cast high speed steel roll is made of alloy ductile iron, thus, the roll neck strength is strong.

| Chemical Element | C | Si | Mn | Cr | Ni | Mo | V | W | P | S |

| HSS % | 1.50~2.20 | 0.30~1.00 | 0.40~1.20 | 3.00~8.00 | 0.00~1.50 | 2.00~8.00 | 2.00~9.00 | 0.00~8.00 | ≤0.030 | ≤0.025 |