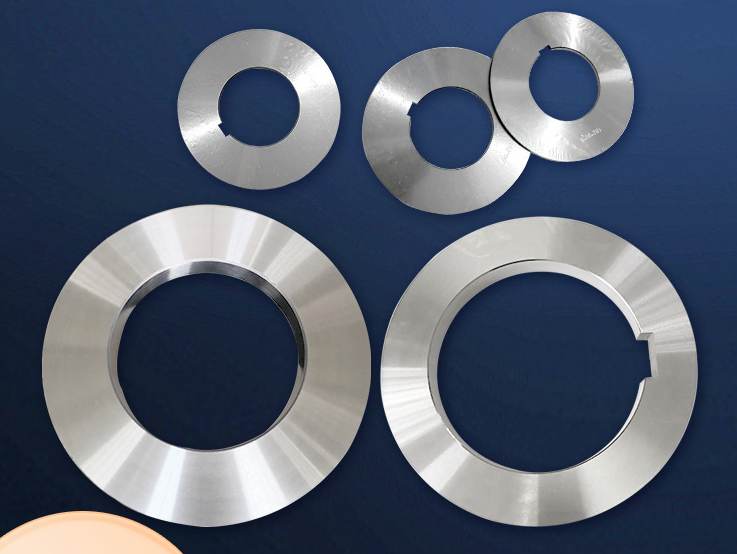

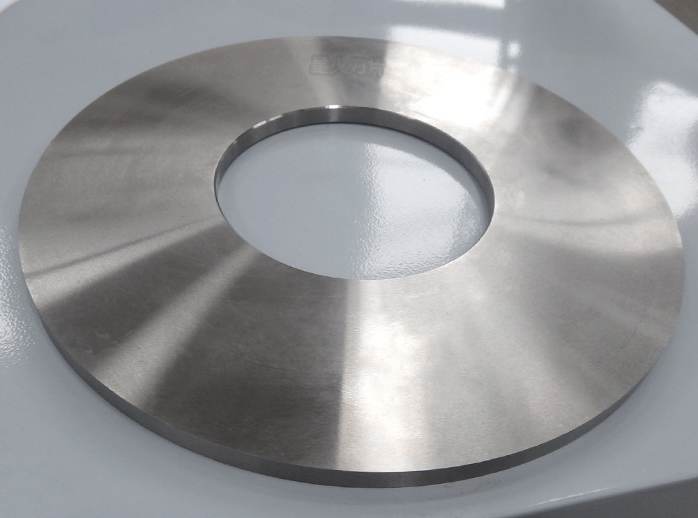

Disc Rotary Shear Blade

The disc rotary shear blade used in the metallurgical strip steel slitting industry, also known as the strip cutting machine blade, rotary shear machine blade, rotary shear machine round blade, longitudinal slitting machine blade, disc blade, etc. It is mainly used for slitting items such as paper, film, gold and silver foil, copper foil, aluminum foil, and magnetic tape. It requires that the blade has small cutting resistance and great wear resistance. Due to the requirement for the accuracy of goods, the cutting edge sometimes needs to reach micron-level accuracy.

The main materials used for the blade of the slitting machine are T10, 6CrW2Si, Cr12MoV, LD, H13, W18Cr4V and other high-quality tool steels and high-alloy die steels, which are widely used in trimming and stripping of thin, medium and thick plates, such as hot-rolled coil pipes, pickled plates, electroplated and colored steel plates, silicon steel plates, stainless steel, and sand steel sheets. The general materials include W18Cr4V, W6Mo5Cr4V (SKH), Cr12MoV (SKD1), 9CrSi, 65Mn, etc.

The incision of the blade of the slitting machine made by TINVO is smooth and flat, the cutting edge is resistant to wear and tear // within 0.003, the thickness tolerance is ±0.001, and the finish can reach within 0.8. New materials such as W6Mo5Cr4V2Co(A1) and SLDDC53 have unique toughness and wear resistance, which are especially suitable for the precise slitting of 0.1-10mm stainless steel. The cutting edge of the blade of the slitting machine is sharp and resistant to wear, the incision is smooth and straight, there are many product specifications and a complete variety, and non-standard products can be processed and customized according to customer requirements.

We can process according to the client's requirements and drawings, leave a message for more details