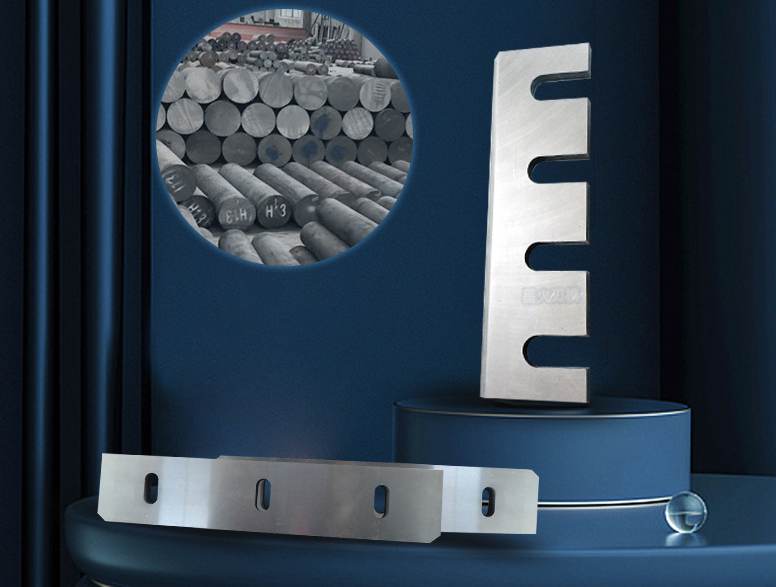

Blade of the grinder / Blade of the pulverizer.

The materials of the grinder blades include T10, 9CrSi, 6CrW2Si, Cr12MoV, SKD11D2, W18Cr4V, and hard alloy (steel). There are many varieties and complete specifications of plastic machinery blades produced, mainly including powder plastic grinder blades, plastic film sealing and cutting blades, plastic grinder blades for plastics, alloy plastic granulator tools, cutting blades for front steel sealing machines, hob blades for plastic pelletizers, plastic rotary cutting blades.

The plastic machinery blades are mainly used in crushers in the plastic and rubber industries. Like other blades, it requires precise geometrical dimension tolerances to ensure good assembly quality with the machine. It needs to meet the different needs of users and the selection of the chemical composition of the blade material for cutting different objects. It needs a suitable blade edge angle, that is, to keep the blade edge sharp while also giving the blade a certain strength without blunting during use. It requires a good heat treatment process to achieve the suitable hardness and very small internal stress of the blade, so that it will not deform during use. We supply various types of standard and special-shaped tools for plastic machinery in stock for you.

Non-standard plastic machinery blade products can be customized according to the drawings, specifications, blade material, hardness value and other requirements provided by the customer. The material of the crusher blade is 65Mn spring steel, 9crsi, SK5, T10, etc., and the heat treatment hardness is IRC52-55 degrees.

We can process according to the client's requirements and drawings, leave a message for more details