Automatic Anti-Eccentric Wear Oval Sucker Rod Centralizer

Automatic Anti-Eccentric Wear Oval Sucker Rod Centralizer

With the development and production of oil fields, the eccentric wear of sucker rod and tubing is becoming increasingly serious due to the influence of well deviation and well structure. We newly developed an automatic anti-eccentric wear oval sucker rod centralizer for solving this problem, which has obtained an invention patent. There are two specifications, 19mm (3/4") and 22mm (7/8"), with 3/4" being 232mm long and 7/8" being 239mm long, and it is designed to be used in 2⅞" tubings.

With the development and production of oil fields, the eccentric wear of sucker rod and tubing is becoming increasingly serious due to the influence of well deviation and well structure. We newly developed an automatic anti-eccentric wear oval sucker rod centralizer for solving this problem, which has obtained an invention patent. There are two specifications, 19mm (3/4") and 22mm (7/8"), with 3/4" being 232mm long and 7/8" being 239mm long, and it is designed to be used in 2⅞" tubings.

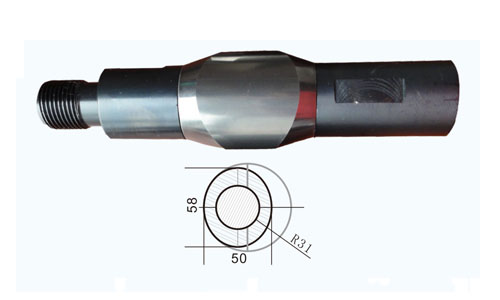

The cross-sectional outer contour of the centralizing body of this centralizer is oval, and the maximum radius is equal to the inner hole radius of the 2⅞" tubing. The centralizing body of the centralizer can not only automatically rotate axially, but also automatically adjust the inclination angle with the bending change of the tubing to ensure that the largest arc surface of the centralizing body and the arc surface with the same radius as the inner hole radius of the (2⅞") tubing always remain in surface contact, which greatly reduces the pressure borne by the unit area of the tubing wall.

Since this type of centralizing body is made of alloy material, the surface hardness is equivalent to that of hard alloy, and the surface roughness is like a mirror surface, so the wear of this type of sucker rod centralizer on the tubing and tubing itself is too small to be negligible, and the service life can reach several times that of the conventional centralizer. When in use, the centralizer can be directly connected to the corresponding sucker rod.

If you have special requirement and query, please leave a message for the further details