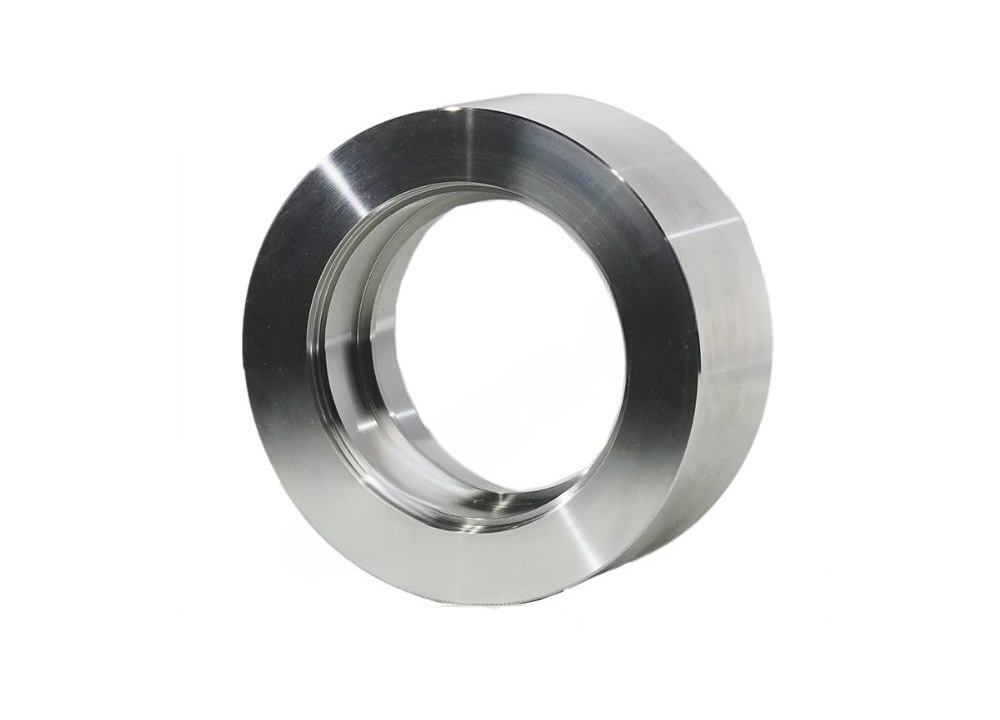

H-beam Universal Rolling Mill Roll Ring

Product specifications: °200-°850

Material: High performance high-speed steel(HSS)

This series of material is a new material developed by our company, which is mainly used for the universal rolling mill roll rings of section steel rolling production line. The surface hardness of the HSS roll ring is HSD 85-90, the hardness drop/10mm is≤3HSD, and the single grinding amount is small.

This mill roll ring can be used for 7-8 cycles, and the total steel passing amount can reach 2-3 times that of adamite roll rings, which has a high cost effectiveness advantage. This material has high wear resistance and impact toughness under thermal load, and can effectively control the size of the section steel and improve the surface quality of the steel parts during the rolling process. The frequency of slot changing is low, effectively improving the operating rate, reducing faults and energy consumption, reducing the labor intensity of the workers, etc. At the same time, there will be no falling blocks, and the processing difficulty is low, making it suitable for the universal rolling mills of section steel rolling production lines. There will be no phenomenon of falling blocks or exploding rings, CNC lathes can be used for processing, which has high processing efficiency and low cost and is conducive to reducing the amount of backup rollers, vertical roller suitable for universal rolling mills in section steel production lines.