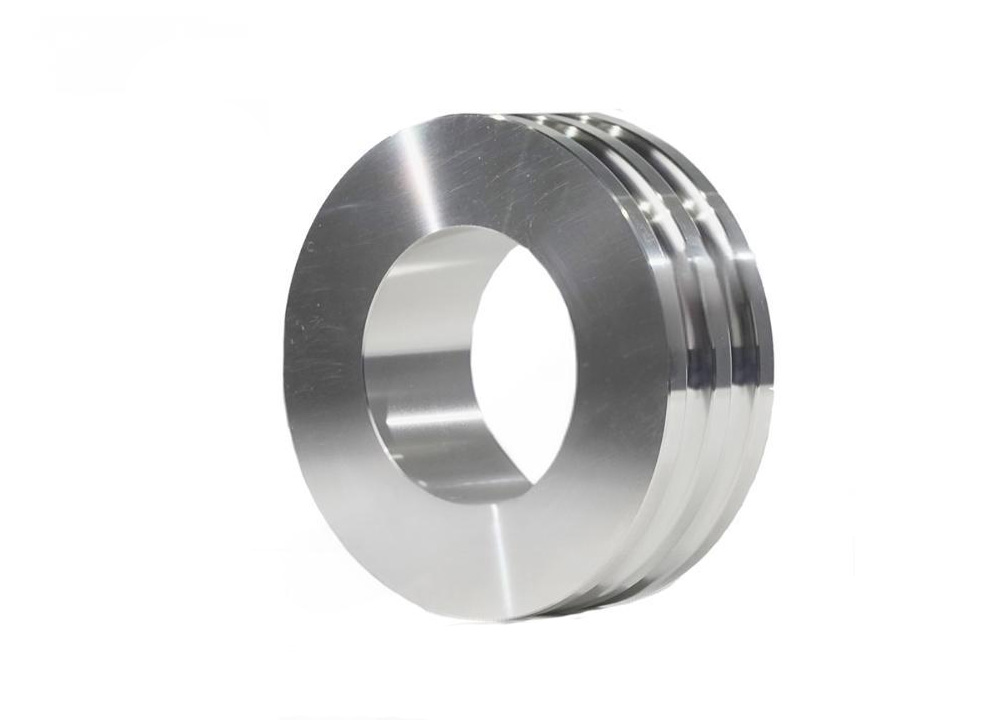

High Speed Steel Bar Precision Rolling Mill Roll Ring

Product specifications:°150-°350

Material: High performance high-speed steel(HSS)

This series of material is a new type of material developed by our company for the mill roll rings of the high-speed steel bar pre-precision rolling mill, with a hardness of HSD85-90. The hardness difference on roller surface ≤3HSD, hardness drop: ≤ 2HSD, single grounding amount is small.

This material has high wear-resistance and impact toughness under thermal load, so the product not only has high wear resistance characteristic, but also is less prone to ring explosion in pre-precision rolling stands with larger material types and deformations than hard alloys. At the same time, CNC lathes can be used for processing, which has high processing efficiency and low cost and is conducive to reducing the amount of backup rollers, The total amount of steel passing through each group of roll rings can reach over 60% of that of hard ally roll rings, but the price is less than one-third of that of harden alloy roller rings, which has a very high cost performance advantage, suitable for pre precision rolling of high-speed bar.

High Speed Steel Wire Rod Pre Precision Rolling Mill Roll Ring

Product specifications:°150-°320

Material: High performance high-speed steel(HSS)

This series of material is a new type of material developed by our company for the mill roll rings of the pre-precision rolling mill of high-speed wire rods, with a hardness of HSD88-93. Unifomity of roller surface hardness ≤3HSD, hardness drop/10mm: ≤ 2HSD,single grounding amount (reduction): ≤0.8mm.

This material has high wear-resistance and impact toughness under thermal load, so the product not only has high wear resistance characteristic, but also is less prone to ring explosion in pre-precision rolling stands with larger material types and deformations than hard alloys. At the same time, CNC lathes can be used for processing, which has high processing efficiency and low cost and is conducive to reducing the amount of backup rollers, The total amount of steel passing through each group of roll rings can reach over 70% of that of hard alloy roll rings, and the price is less than 40% of that of harden alloy roller rings, which has a very high cost performance advantage, suitable for pre precision rolling of high-speed wire rods.