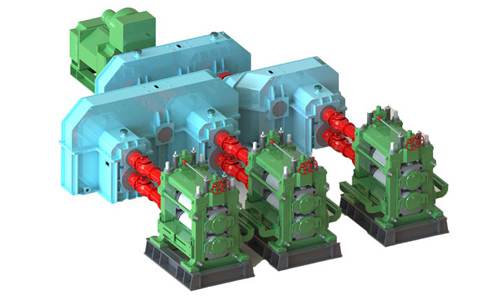

Φ200-650 Hot Rolling Mill Machine

Introduction

Φ200-650 hot rolling mill machine adopts a three-roll working base, used for rolling small steel bars. The configuration of the machine is electric motor - gear reducer - gear housing - rolling mill. The rolling mill reducer is with a center distance of 600-700mm. Since the steering and rotational speed of the rolls are irreversible, the prime driven power applies a high-speed AC main motor with a lower cost. Considering that the rolling load is very uneven, a flywheel is added between the gear reducer and the motor in order to balance the motor load. The purpose of the gear housing is to transmit torque to the work roll. Three cylindrical herringbone gears of equal diameter are arranged in a row on the vertical plane of a closed box.

Φ200-350 rolling mill is the equipment of metal hot rolling mill process, which mainly refers to 2-hi roll reversible rolling mill and 3-hi roll reversible rolling mill. The working structure is composed of mill rolls, roll bearings, rolling mill guides, rack, rail seat, roll adjusting device, upper roll balancing device, and roll changing device.

Φ650 rolling mill is generally used as a cogging machine in the rolling mill production line. It is used to roll the slab introduced from the furnace to obtain the desired shape, size, texture and properties, for the lower mill to bite-in. Because the rolled parts just coming out from the heating furnace has the characteristics of high temperature, good plasticity, low deformation resistance, large the pressing amount of the cogging machine (generally up to 50%), the roll of rolling mill is large, and finally, the rolled product has good performance and no residual stress, no bubble, small crystal grain, dense inside texture.

Specification

Model | Power (KW) | Rolling line speed (m/s) | Production (T) | Rolling Force (T) | Feeding product | Weight (T) | Rolling capacity | Finish product |

JZ200 | 22-30 | 1.2 | 1.5-3 | 30×30square billet | 2.2 | below ф20 | Deformed bar, flat steel, square steel, etc | |

ф200×2 | 75/100 | 1.5 | 3-5 | 20 | 30×30square billet | 6.8-8.6 | Below ф20 | Deformed bar, flat steel,square steel, etc |

ф200×3 | ||||||||

ф220×3 | 130/155 | 1.5-2 | 4-8 | 25 | 50×50square billet | 14.3 | Below ф25 | Deformed bar, flat steel, square steel, etc |

ф250×2 | 185/240 | 1.8-2.5 | 5-15 | 30 | 60×60square billet | 22.5/27.5 | Below ф34 | Deformed bar, flat steel, square steel angle steel, etc |

ф250×3 | ||||||||

ф250×5 | 500 | 2.5-5 | 30-40 | 30 | 60×60square billet | 38 | 6.5 wire | All |

ф300×2 | 380/560 | 2-2.5 | 10-15 | 50 | 90×90square billet | 43.6/58 | Below ф36 | Deform rebar, angle steel, channel steel

|

ф300×3 | 20-30 | |||||||

ф300×5 | 630 | 2-2.5 | 50-100 | 50 | 90×90square billet | 88 | Below ф36 | Deform rebar, angle steel, channel steel |

ф350×2 | 680 | 2-2.5 | 30-50 | 80 | 100×100square billet | 65/80 | All | / |

ф350×3 | 40-60 | |||||||

ф350×5 | 800 | 2-2.5 | 80-120 | 80 | 100×100square billet | 115 | All | / |

ф400×2 | 850 | 2-2.5 | 50-100 | 100 | 120×120square billet | 84 | 40-90 cm2 | / |

ф500×2 | 1000 | 2-2.5 | 150 | 150 | 165×165×1400 | 152 | 50 -100 cm2 | / |

ф600 | 1600 | 2.5 | 200 | 250 | 200×200 | 180T | Cogging machine |

TINVO Hot Rolling Mill

TINVO provides the hot rolling mill line to finish the whole hot rolling process. The main equipment includes Reheating Furnace, High-Pressure Water Descaling, Mill Stands, Flying Shear, Cold Shear, Cooling Bed, Packing and Collection Machine, Electric, Air, Lubrication System, etc. The hot strip machines are the most commonly used. The process is that Scrap steel ----melting---- casting----mold unloading----sorting-----deliver to reheating furnace----heating to 1150~1200°C---- come out furnace---- rolling---- finished product ----packing. TINVO offers design, manufacture and onsite service of the whole bar or rebar hot rolling line with computer control for advanced international standards.

Hot rolling refers to rolling performed above the metal recrystallization temperature. When the annealing temperature is high enough and the time is long enough. new strains (recrystallized cores) without stress change are generated in the fiber structure of the deformed metal or alloy, and the new grains continue to grow until the original deformed structure completely disappears, the properties of metals or alloys also change significantly. This process is called recrystallization. The temperature at which new grains begin to form is called the recrystallization temperature. The temperature at which the microstructure is completely occupied by the new grains is called the end recrystallization temperature. Generally, the recrystallization temperature is mainly affected by the alloy composition, the degree of deformation, the original grain size, and the annealing temperature.

The Features of Hot Rolling

Low energy consumption, good plastic working, low deformation resistance, insignificant work hardening, easy rolling, and reduced energy consumption required for metal deformation.

Hot rolling mill usually uses large ingots/billet and large degrees of down rolling. The production speed is fast and the yield is high, which creates conditions for large-scale production.

The cast structure is transformed into the processed structure by hot rolling, and the plasticity of the material is greatly improved through the transformation of the structure.

The characteristics of the rolling method determine that there is anisotropy in the properties of the rolled parts. Firstly, there are obvious performance differences in the longitudinal, horizontal and high directions of the material. Secondly, there is an obvious directionality in the performance.