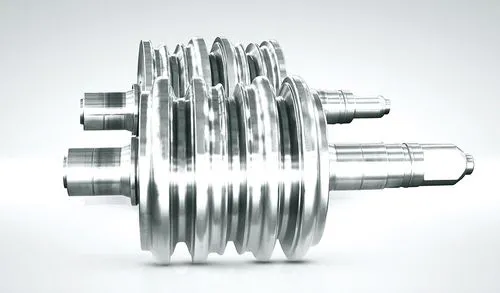

Adamite Roll

Introduction

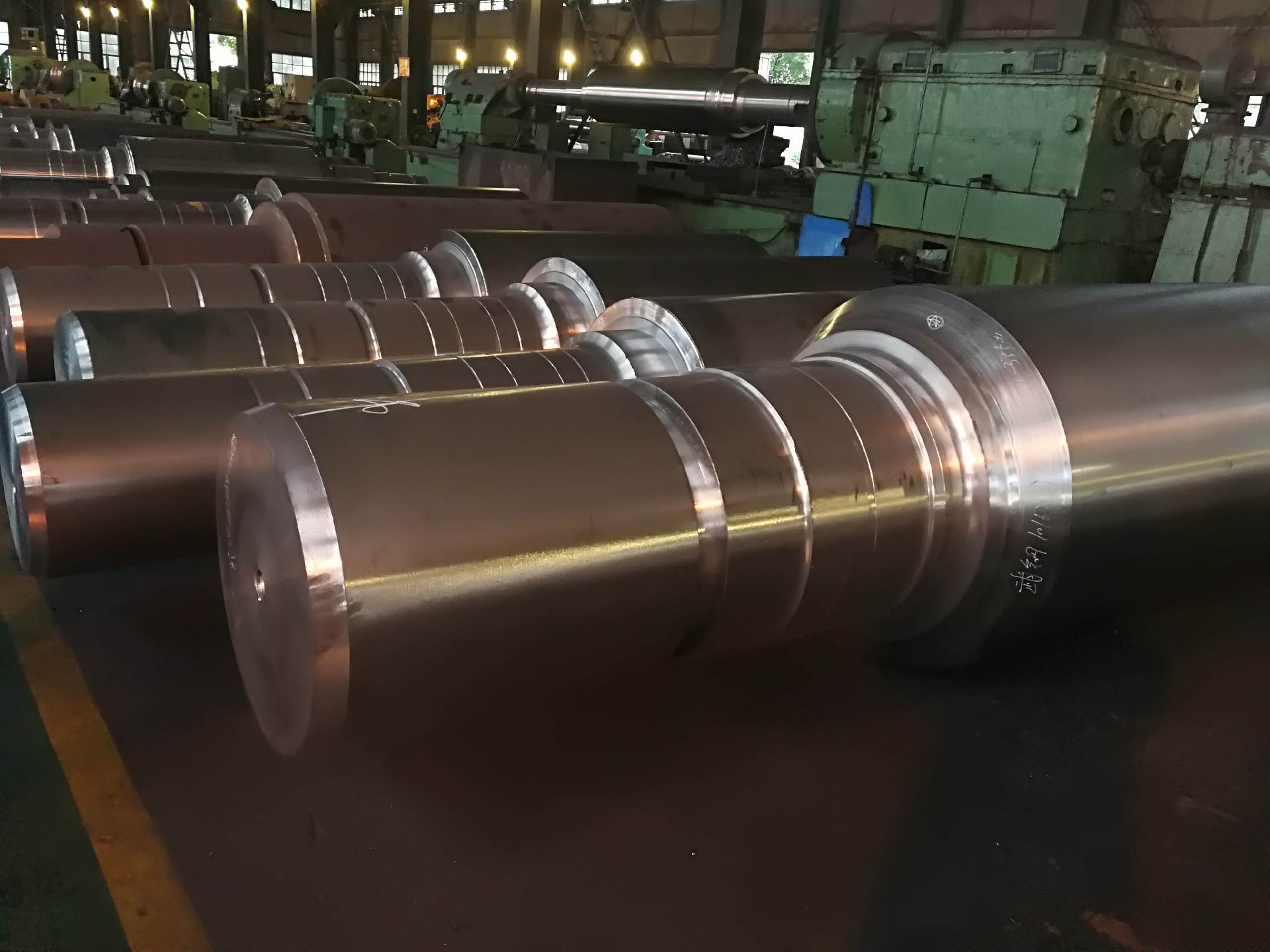

The semi-steel adamite roll is casted as a whole and there is no weak interface in compound casting roll, thus it has a better capacity, strength and toughness than cast iron roll. This kind of mill rolls can be used as work roll, back-up roll and vertical roll for large-class and medium-class rough rolling mill and intermediate rolling mill of section steel, wire rod, rail beams, steel billet, hot rolling steel strip.

Most of the adamite steel rolls are produced by the static integral casting method. It must be subjected to high-temperature diffusion annealing. Generally, adamite rolls for steel rolling mills are required to control the total amount of non-metallic inclusions below 0.05%. The centrifugal composite semi-steel back-up rolls are made of adamite steel material, the body and neck of the rolls are made of nodular cast iron, and they have been successfully used in hot-rolled strip steel finishing mill. The semi-steel roll ring is produced by composite centrifugal casting. The outer layer of the roll ring is high-carbon semi-steel. The inner layer of the roll ring is graphite steel or ductile iron. Use a high-speed rotating centrifuge to make two different types of molten steel poured and cast.

Adamite Roll Chemical Composition

Alloy Materials | C | Si | Mn | P | S | Ni | Cr | Mo |

ZuB140CrNiMo | 1.30~1.50 | 0.30~0.60 | 0.70~1.10 | ≤0.035 | ≤0.030 | 0.20~0.80 | 0.80~1.20 | 0.20~0.60 |

ZuB160CrNiMo | 1.50~1.70 | 0.30~0.60 | 0.70~1.10 | ≤0.035 | ≤0.030 | 0.20~1.00 | 0.80~1.20 | 0.20~0.60 |

ZuB180CrNiMo | 1.70~1.90 | 0.30~1.00 | 0.70~1.20 | ≤0.035 | ≤0.030 | 0.60~1.50 | 1.00~1.50 | 0.20~0.80 |

ZuB200CrNiMo | 1.90~2.10 | 0.30~1.00 | 0.70~1.20 | ≤0.035 | ≤0.030 | 1.00~2.00 | 1.20~2.00 | 0.20~0.80 |

Physical Properties

Alloy Materials | Roll-body hardness HSD | Tensile strength Mpa | Ductility % | Impact toughness J/cm |

ZuB140CrNiMo | 35~45 | ≥590 | ≥1.0 | ≥4 |

ZuB160CrNiMo | 38~53 | ≥540 | ≥1.0 | ≥4 |

ZuB180CrNiMo | 42~55 | ≥500 | ≥0.5 | ≥4 |

ZuB200CrNiMo | 45~60 | ≥450 | ≥0.5 | ≥4 |

Metallographic Structure

The metallurgical structure of roll-body work layer: Pearlite + carbide or fine pearlite + a little bainite + carbide