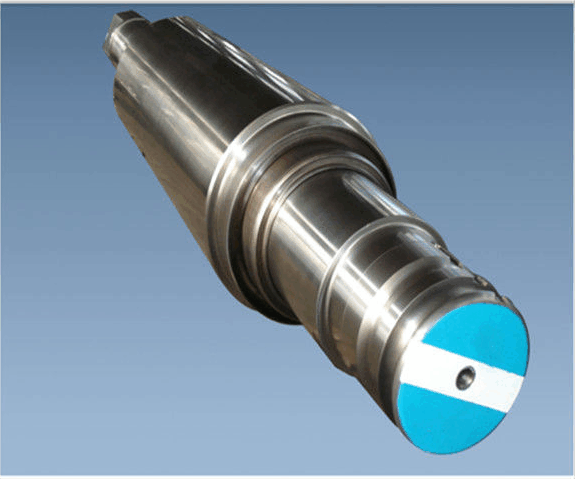

Graphitic Steel Roll

Introduction

Graphitic Steel roll is in semi-finished condition. The carbon content and matrix are similar to adamite roll. It also has some features and usage similar to semi-steel roll. The microstructure consists of pearlite, carbide and precipitated graphite, which acts to improve wear-resistance and hardness. The roll is ideal for mills having problems with firecracking. It can be widely used as a work roll of medium plate reversible rolling mill, two-high strip mills machine, medium plate reversible rolling mill, rough rolling mill, blooming mill, steel billet rolling mill, high-speed wire rod roughing mill.

The graphitic steel roll refers to add an appropriate amount of inoculant alloy and nodulizing agent in the molten steel through controlling the content of graphitizing elements and carbide forming elements and the corresponding proportion, to inoculate and nodulate During the solidification process, the rolls form spherical or agglomerated graphite.

The carbon content of graphite steel rolls is equivalent to that of semi-steel roller. The microstructure of the matrix is similar to that of a semi-steel roller. There are still wear-resistant particles with granular and rod-shaped carbides in the matrix structure, and there is a certain amount of spherical graphite in the matrix structure. According to the purpose of the roll, the carbon content, alloy element content, and hardness requirements of the graphite steel roll can be adjusted, and the content and morphology of carbide and graphite in the structure can be controlled.

Chemical Composition

Graphite Steel | C | Si | Mn | P | S | Ni | Cr | Mo |

ZuS140SiCrNiMo | 1.30~1.50 | 1.30~1.60 | 0.50~0.80 | ≤0.035 | ≤0.030 | 0.20~0.60 | 0.40~0.70 | 0.20~0.50 |

ZuS150SiCrNiMo | 1.40~1.60 | 1.00~1.40 | 0.60~1.00 | ≤0.035 | ≤0.030 | 0.35~1.00 | 0.60~1.00 | 0.20~0.50 |

ZuS160SiCrNiMo | 1.50~1.70 | 1.00~1.40 | 0.60~1.00 | ≤0.035 | ≤0.030 | 0.50~1.50 | 0.60~1.60 | 0.20~0.50 |

ZuS170SiCrNiMo | 1.60~1.80 | 1.00~1.40 | 0.60~1.00 | ≤0.035 | ≤0.030 | 0.80~2.00 | 0.60~2.00 | 0.20~0.50 |

Physical Properties

Graphite Steel | Roll-body hardness HSD | Tensile strength Mpa |

ZuS140SiCrNiMo | 36~46 | ≥660 |

ZuS150SiCrNiMo | 40~50 | ≥600 |

ZuS160SiCrNiMo | 42~52 | ≥550 |

ZuS170SiCrNiMo | 45~55 | ≥550 |

Metallographic Structure

The metallurgical structure of roll-body work layer: Pearlite + carbide or fine pearlite + a little bainite + carbide