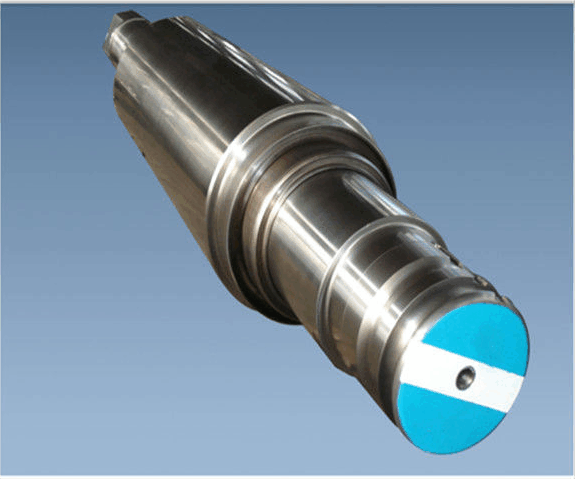

Forged Steel Roll

Introduction

Forged steel rolls have toughness, surface hardness uniformity and fatigue resistance and widely used to the cold rolling mill. The mill rolls are made from steel ingots by forging. Forging can solve metallurgical defects such as loose and shrinkage holes in the ingot, and crush the coarse cast structure to obtain a high-quality roll with dense structure and uniform composition. The production process of forged roll includes smelting, ingot casting, forging, post-forging heat treatment, rough processing, final heat treatment and finishing. The rolls are heat-treated differently depending on the material and application. They are mainly used as strip rolling mill work roll and backup roll, H-type steel universal–shaft, High-speed roll(HSS roll), Cr4 steel backup roll, Cr5 forged steel roll, 86CrMoV7 forged steel roll, 42CrMo forged steel roll, MC2, MC3, MC5, MC6 forged steel roll, etc.

Chemical Composition

Alloy Material | C | Si | Mn | Cr | Mo | V |

42CrMo | 0.38~0.45 | 0.17~0.37 | 0.50~0.80 | 0.90~1.20 | 0.15~0.25 | / |

3%Cr | 0.3~0.55 | 0.2~0.5 | 0.2~1.0 | 2.5~3.5 | 0.2~0.6 | 0.05~0.2 |

5%Cr | 0.3~0.55 | 0.2~0.5 | 0.2~1.0 | 4.5~5.5 | 0.2~0.6 | 0.05~0.2 |

9Cr2Mo | 0.85~0.95 | 0.25~0.45 | 0.2~0.35 | 1.7~2.1 | 0.2~0.4 | / |

Physical Properties

Alloy Materials | Roll-body hardness(HSD) | Tensile strength(Mpa) |

42CrMo | 30~42 | 1080 |

3%Cr | 56~69 | 1100~1470 |

5%Cr | 60~75 | 1200~1500 |

9Cr2Mo | 65~105 | 1100~1400 |